Hi all, first post here and appreciate any assistance you all can provide.

I'm in the process of installing a new timing belt, water pump, pulleys, hydraulic tensioner, etc...

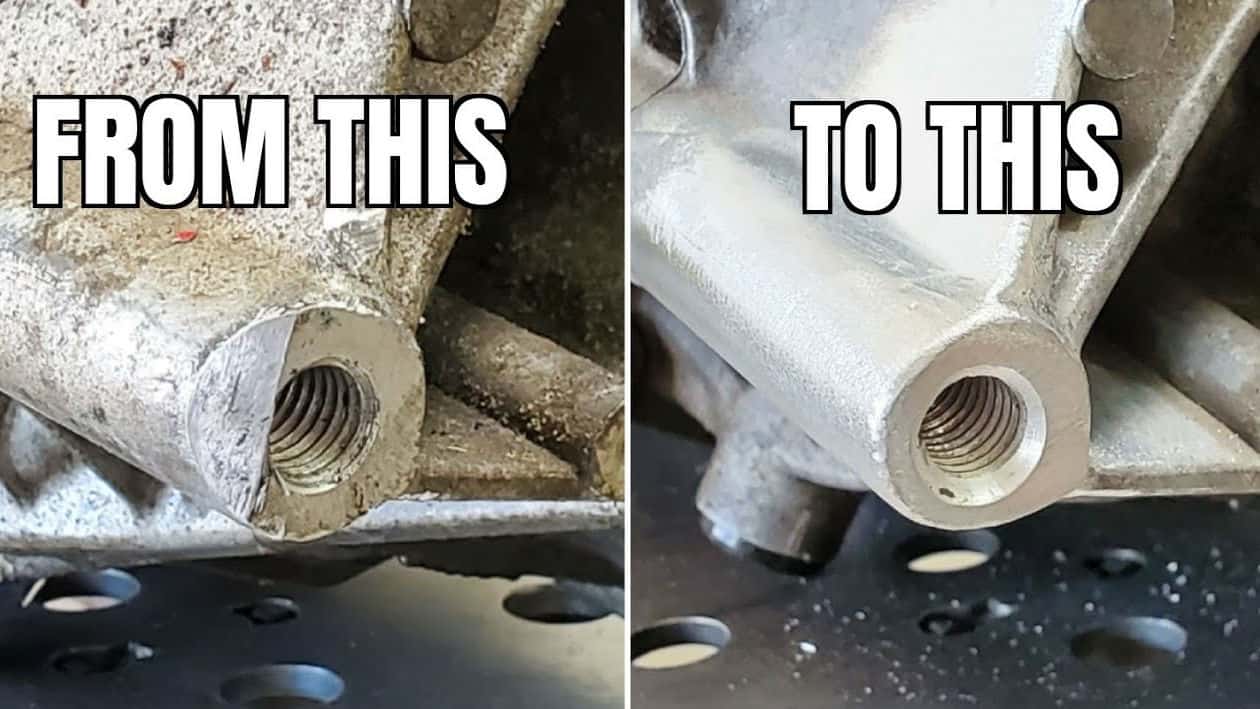

When I unbolted the hydraulic tensioner bolts (2) and removed the tensioner, I noticed the upper left bolt was a different size, slightly bent and the threads were worn. Upon further inspection, I noticed that the previous owner had put a time sert in and half of it is hanging out. This explains why I've had belt slap and possibly why the idler pulley bearings completely disassembled.

If you look at the images, you'll notice that the 10mm bolt removed from the time sert is much shorter than the other bolt. My initial thought is, the previous person who installed a new tensioner broke part of the block and the bolt. They then didn't use a long enough bolt and the bolt eventually rattled out of the time sert. You can see in the images the amount of wear on the tensioner bolt hole and threads on the bolt. Or, they didn't get the time sert in straight due to the lack of space. Multiple things are wrong here.

MY QUESTIONS:

-What should I do going forward?

-Is the engine block toast?

MY INITIAL FIX-IT IDEA:

-Keep the time sert the way it is and buy a much longer bolt than what the specs are. Maybe I can get more threads by reaching further into the block. If I can't get it good and tight, then I would.....

-Clean out the existing time sert and somehow install a new one or put a helicoil in. The only issue is, there's not a lot of meat left on the block given there's another bolt right next to it. Also, I'm not sure how I'd possibly get a good tap in with limited space.

Other car facts:

-car has 258k miles. Last timing belt change was when we bought it @ 187k and had an independent shop replace the timing belt.

Any thoughts, ideas or recommendations?

![525906 525906]()

![525907 525907]()

![525908 525908]()

![525909 525909]()

I'm in the process of installing a new timing belt, water pump, pulleys, hydraulic tensioner, etc...

When I unbolted the hydraulic tensioner bolts (2) and removed the tensioner, I noticed the upper left bolt was a different size, slightly bent and the threads were worn. Upon further inspection, I noticed that the previous owner had put a time sert in and half of it is hanging out. This explains why I've had belt slap and possibly why the idler pulley bearings completely disassembled.

If you look at the images, you'll notice that the 10mm bolt removed from the time sert is much shorter than the other bolt. My initial thought is, the previous person who installed a new tensioner broke part of the block and the bolt. They then didn't use a long enough bolt and the bolt eventually rattled out of the time sert. You can see in the images the amount of wear on the tensioner bolt hole and threads on the bolt. Or, they didn't get the time sert in straight due to the lack of space. Multiple things are wrong here.

MY QUESTIONS:

-What should I do going forward?

-Is the engine block toast?

MY INITIAL FIX-IT IDEA:

-Keep the time sert the way it is and buy a much longer bolt than what the specs are. Maybe I can get more threads by reaching further into the block. If I can't get it good and tight, then I would.....

-Clean out the existing time sert and somehow install a new one or put a helicoil in. The only issue is, there's not a lot of meat left on the block given there's another bolt right next to it. Also, I'm not sure how I'd possibly get a good tap in with limited space.

Other car facts:

-car has 258k miles. Last timing belt change was when we bought it @ 187k and had an independent shop replace the timing belt.

Any thoughts, ideas or recommendations?